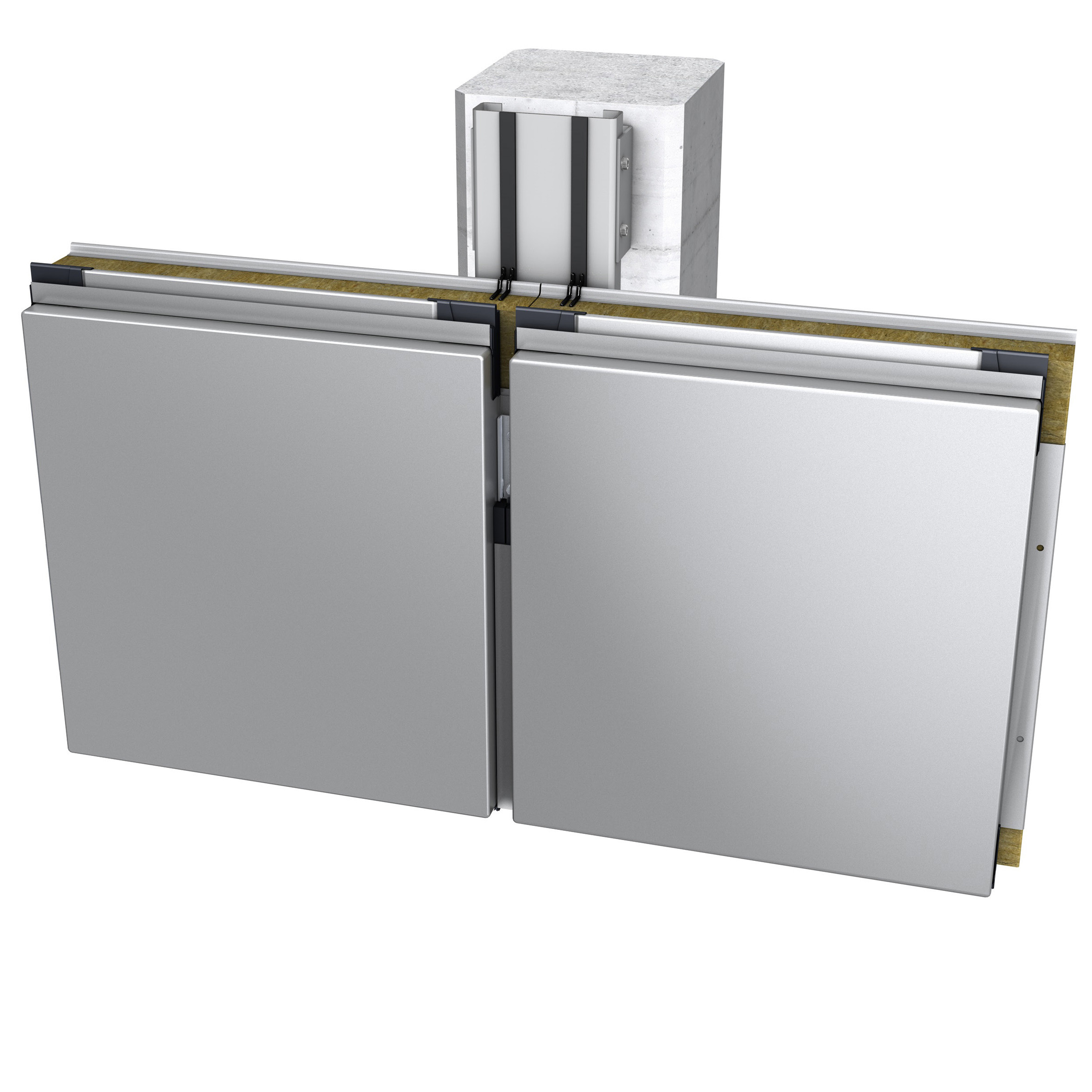

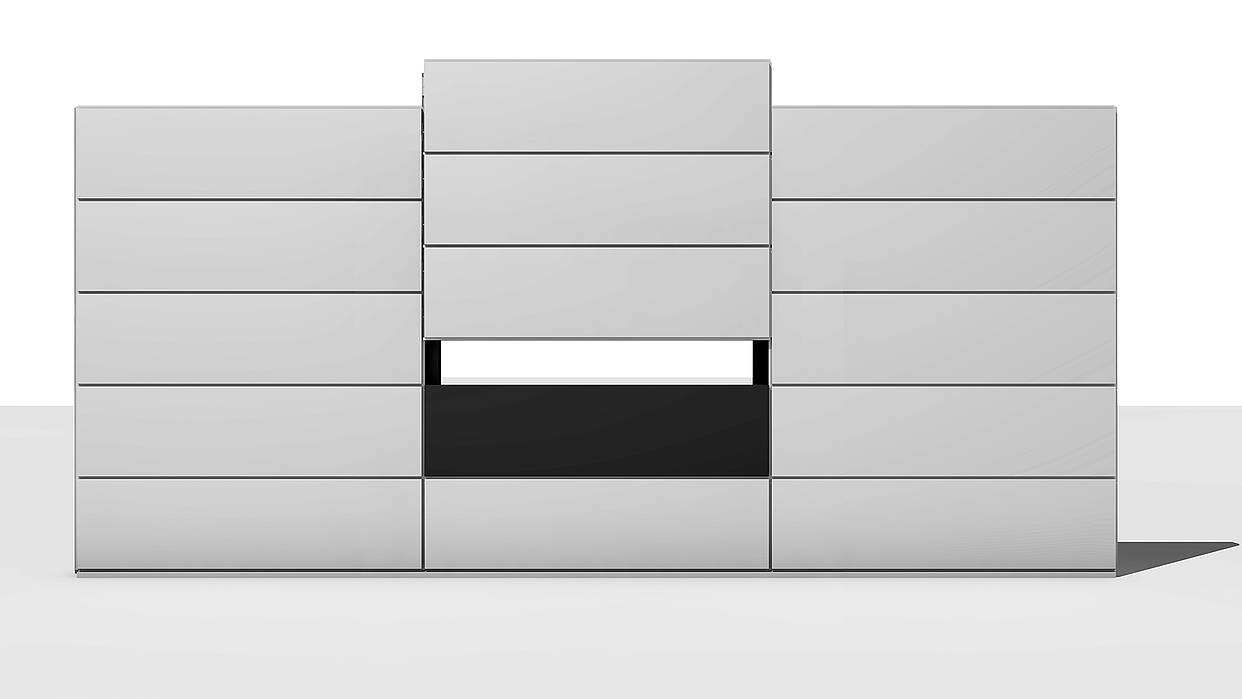

COMPLETE SYSTEM

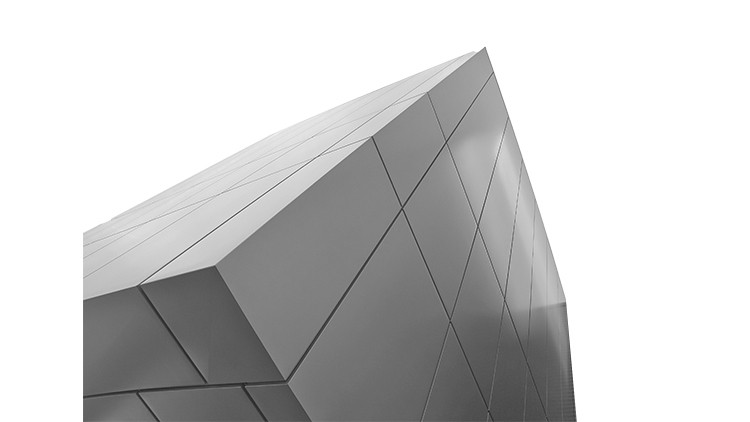

Qbiss One brings a system-approach to the building envelope by uniting all the desired functional advantages of high-quality architectural wall systems with the very best aesthetics. It presents the ultimate combination of aesthetics, design and function.

With all elements prefabricated and manufactured by the latest automated technology, Qbiss One delivers a long-lasting building solution.

The wall system’s main components are:

- Modular façade elements

- Fixing and sealing material

- Architectural performance details

- Corner elements

- Adjustable substructure (optional)

- Windows (optional)

ADVANCED CONSTRUCTION

Prefabricated Qbiss One wall compared to conventional built-up systems

Unlike built-up systems, Qbiss One is a complete all-in-one prefabricated architectural wall solution and therefore replaces the whole built-up system (structural wall + ventilated facade system).

Qbiss One requires non secondary supporting steel work; it can be fixed directly on to primary steelwork or lightweight-gauge steel frame or solid wall. Qbiss One prefabricated wall system is a higher quality solution as components are built in a controlled environment, not on an exposed construction site. It is an efficient and rapidly installed solution that saves time.

In fact, it can offer as much as a 40% time saving when compared with built-up systems and with all the advantages of ease and simplicity. With Qbiss One it is not necessary to consider brick or concrete walls, insulation, vapour and wind protection or additional secondary sub-construction.

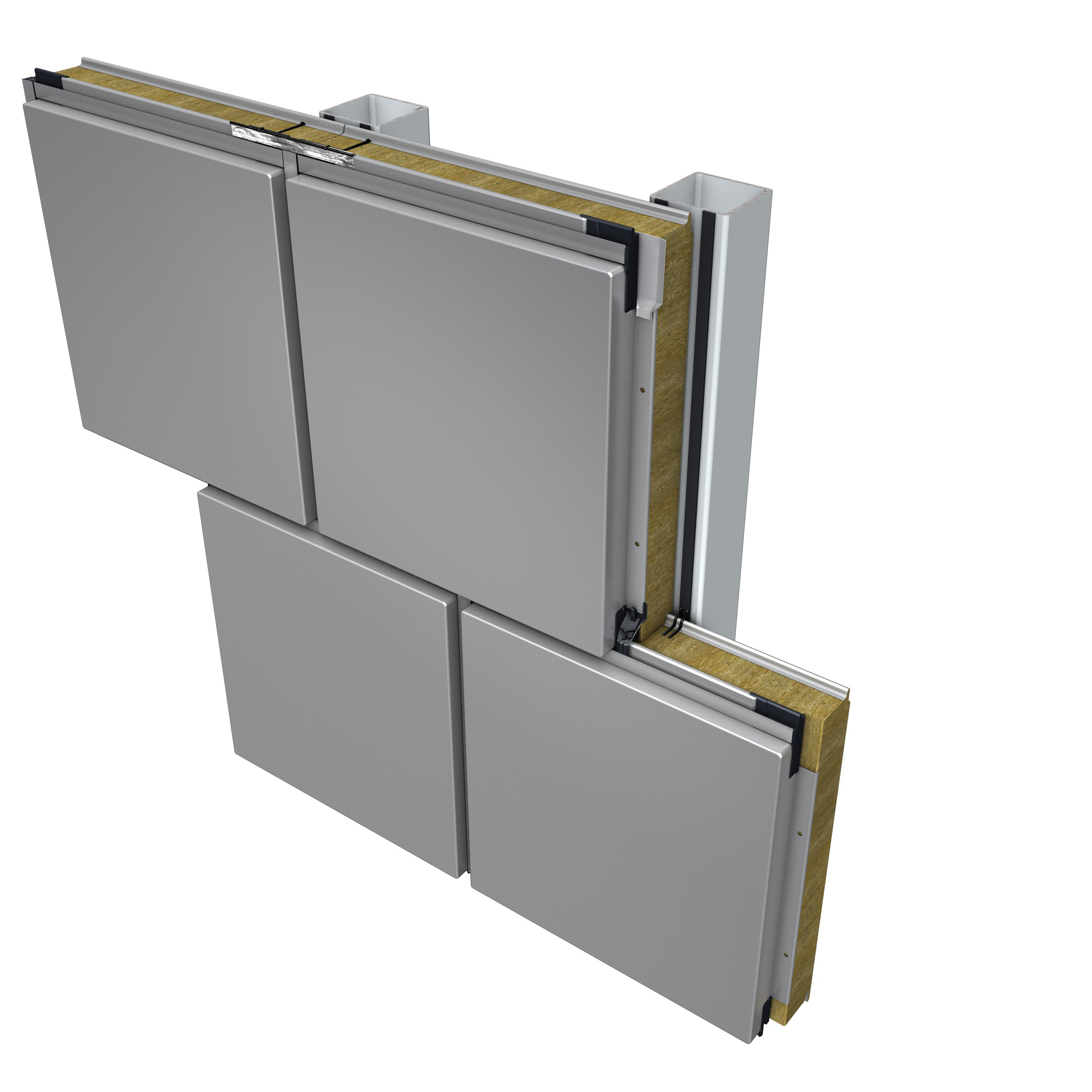

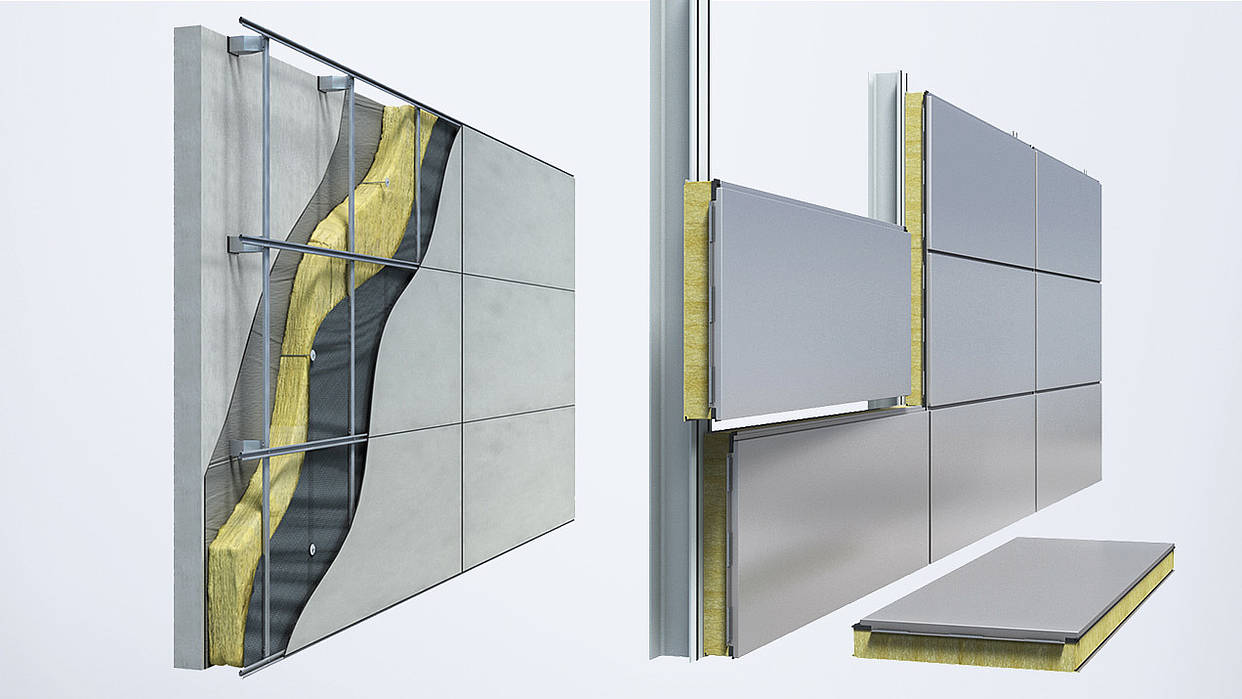

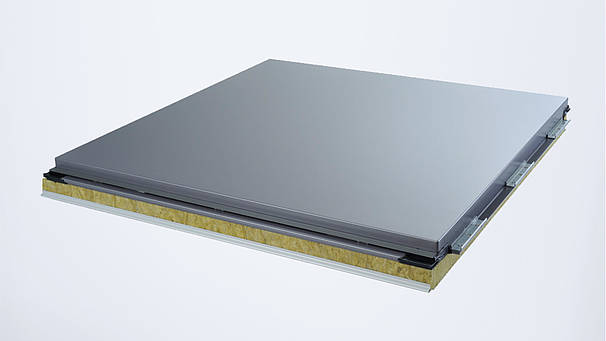

WALL ELEMENT

The basic element of Qbiss One is the modular prefabricated wall element, which is made by an automated and robotic production line.

The prefabricated element is comprised of two galvanised and pre-finished steel sheets (internally 0.5 or 0.6 mm thick and externally 0.7 mm thick). The pre-finished steel sheets are bonded to the core, which is made of non-combustible mineral wool. All three layers make a solid element of thickness ranging 80 – 250 mm.

For instance, where there is no need for insulation Qbiss One is available also as Qbiss Screen.

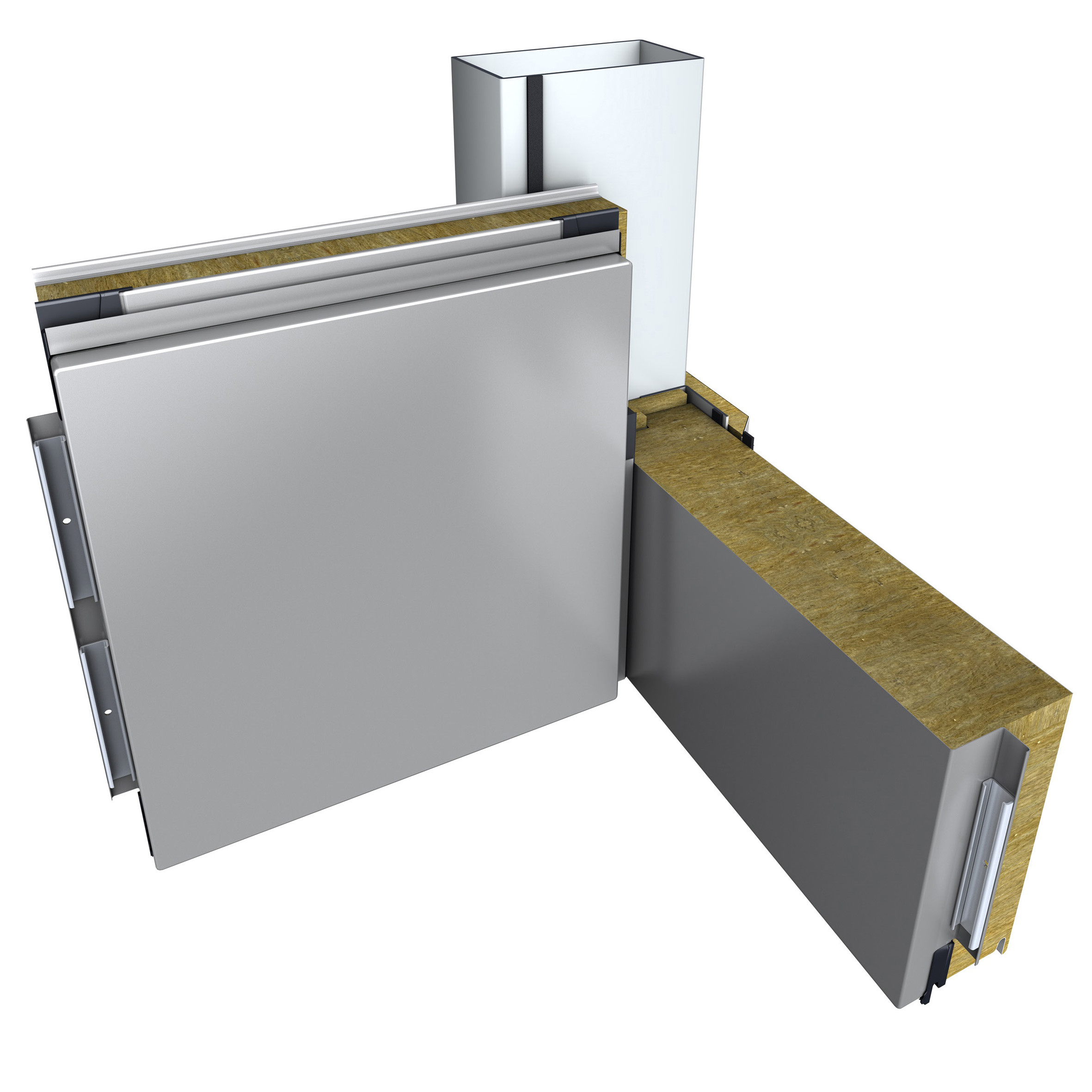

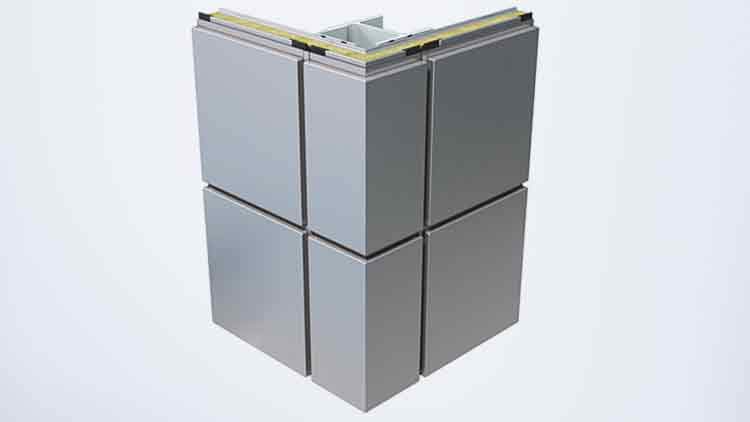

CORNER ELEMENTS

Corner elements make the Qbiss One architectural wall system excel, adding aesthetic value, enabling unique solutions, and complete adaptability to individual buildings. There is a choice between sharp-edge and rounded corner elements.

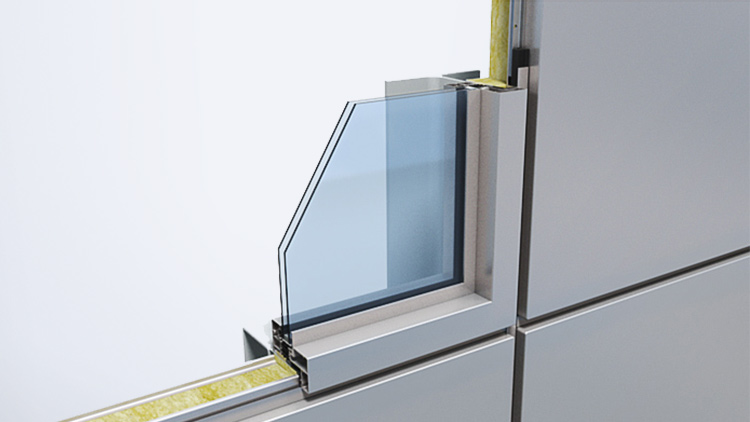

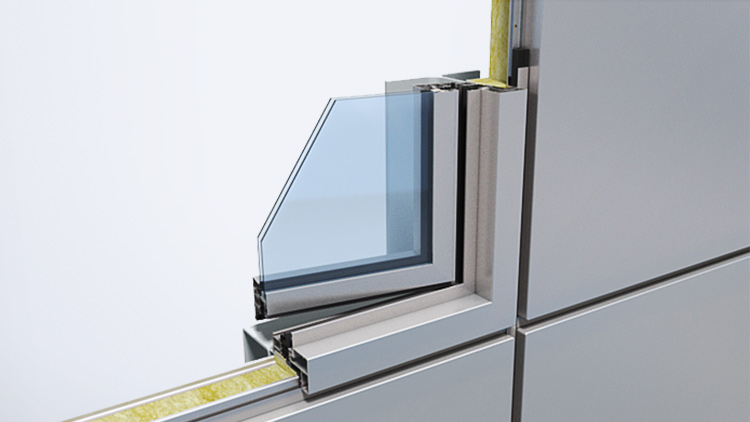

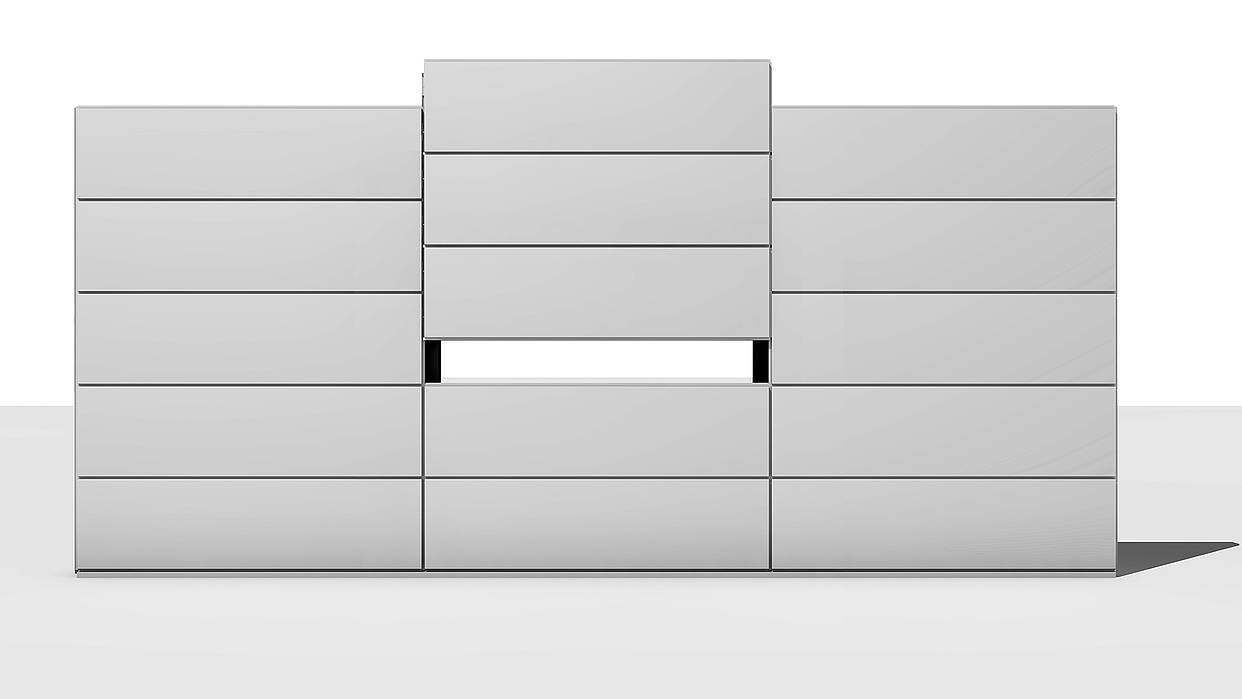

WINDOWS

Qbiss One architectural wall system includes elegant and high-quality integrated window modules and other elements. The window modules are made from high-quality aluminium profiles with an integral thermal break that minimises cold bridges and ensures the highest levels of thermal performance.

Window integration options

Window types

DETAILS

Qbiss One is complemented with the full scope of architectural details. These solutions not only increase design efficiency, but shorten the project design process, as well as ensure the stunning appearance of the building with different typical details available. There is also the ability to create bespoke details for specific project requirements.

FIXING

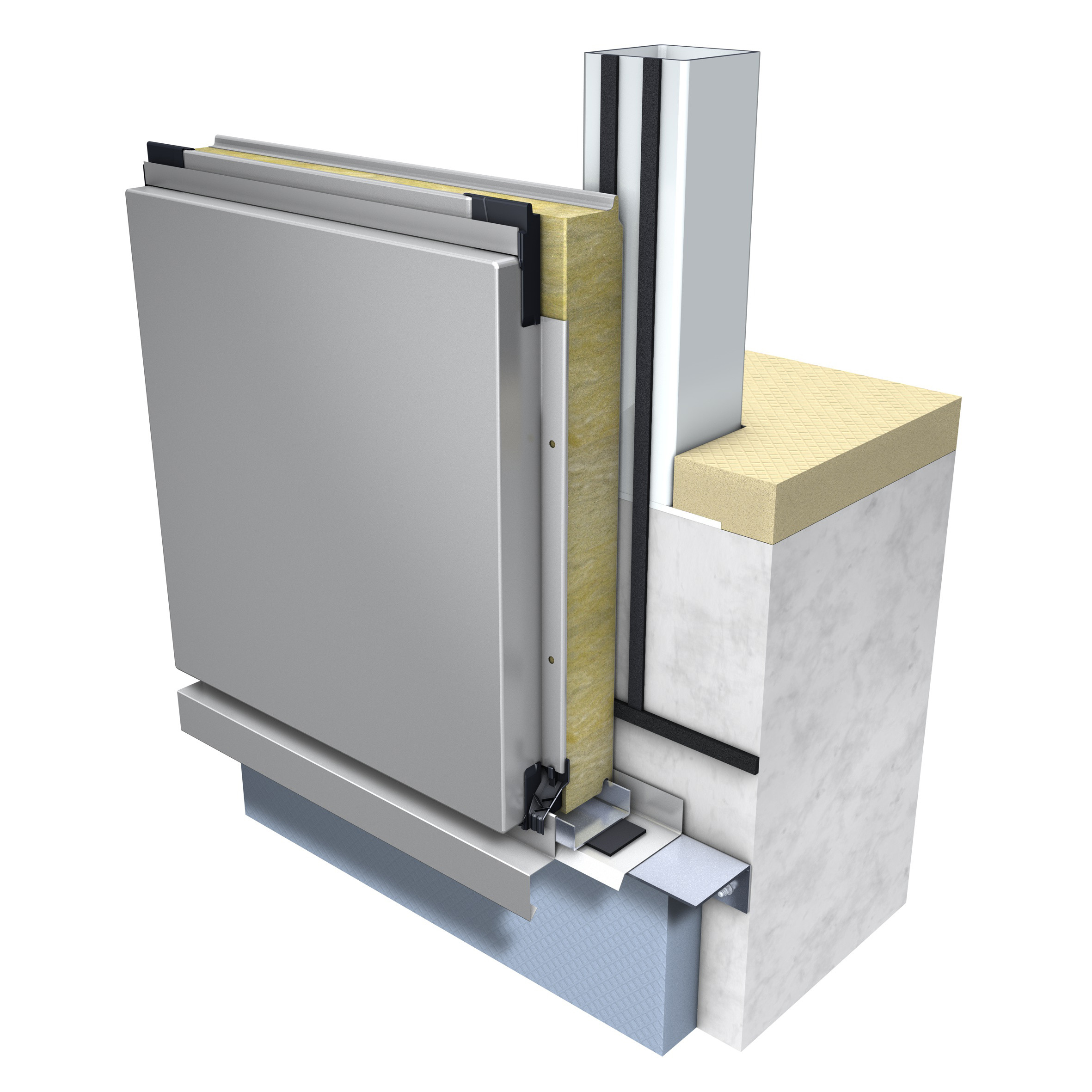

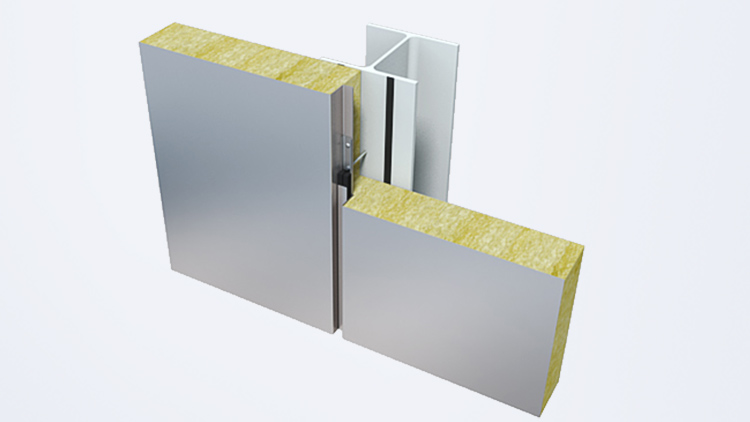

To the steel construction

In instances where the length of a Qbiss One façade element is equal to the grid of the basic structure, the elements can be fixed directly to that steel construction.

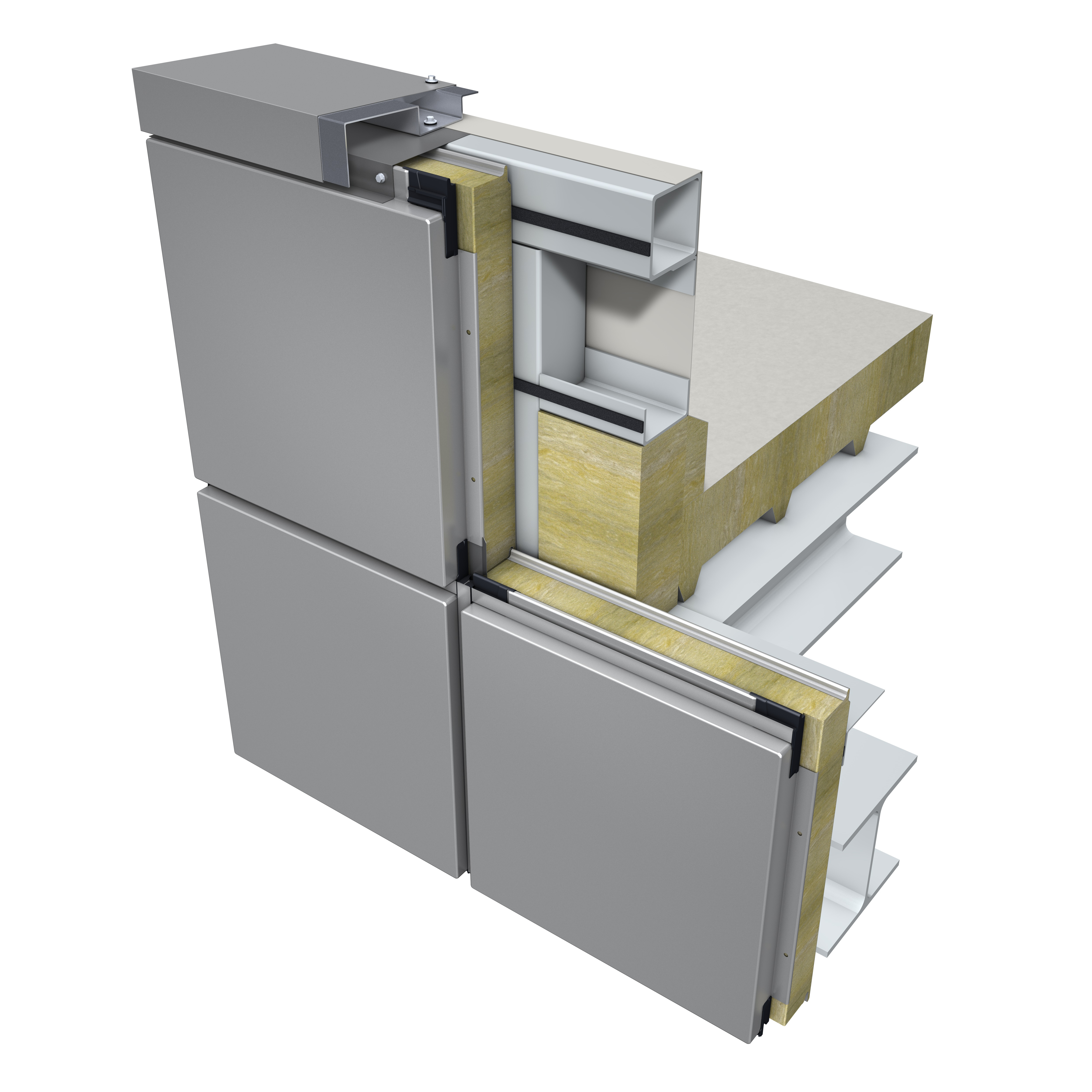

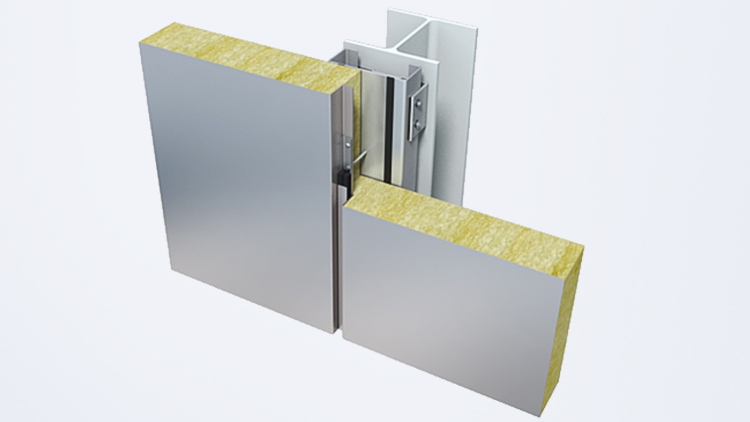

To the steel construction with sub-structure

If the length of elements is shorter than the grid of the basic steel structure, or if the basic construction is not built within the framework of permissible deviations, a levelling sub-structure is required. Suitable static calculations will be required.

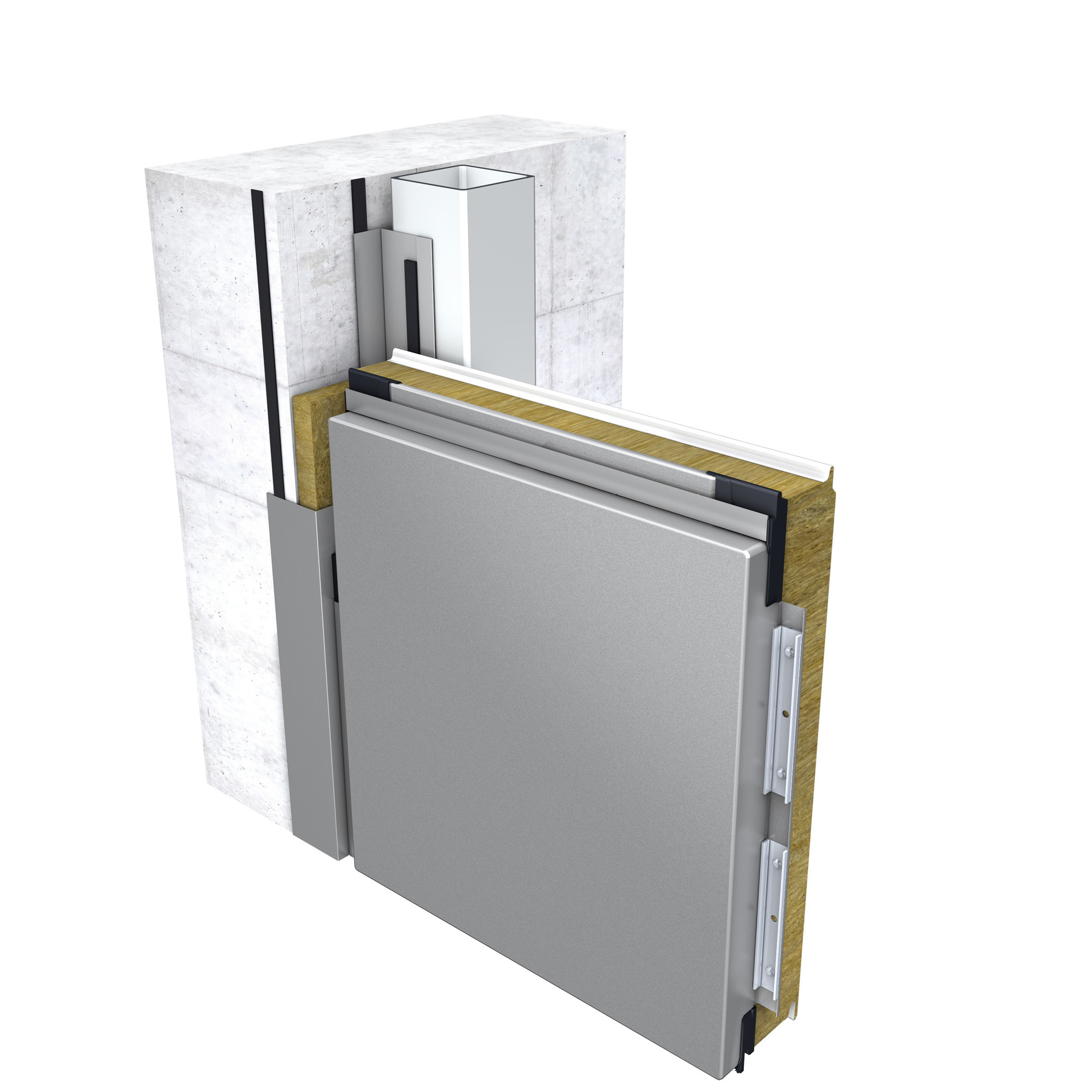

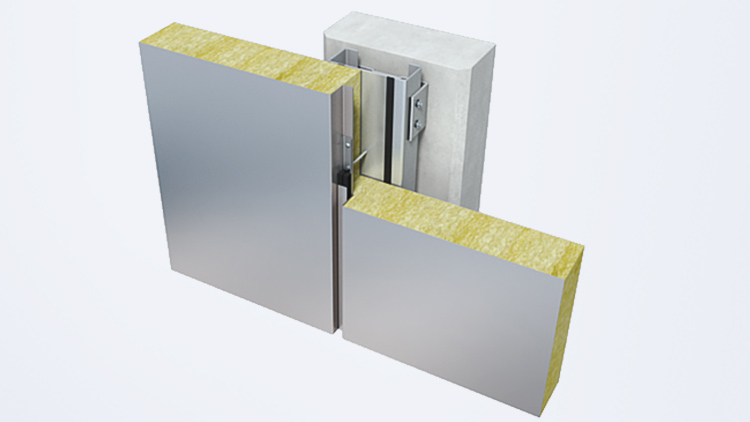

To the concrete construction

A quickly assembled steel sub-structure is used for the installation of Qbiss One elements onto concrete structures, enabling levelling of uneven concrete or brick walls.

Consequently, suitable static calculations will be required and Trimo is able to provide assistance as required.

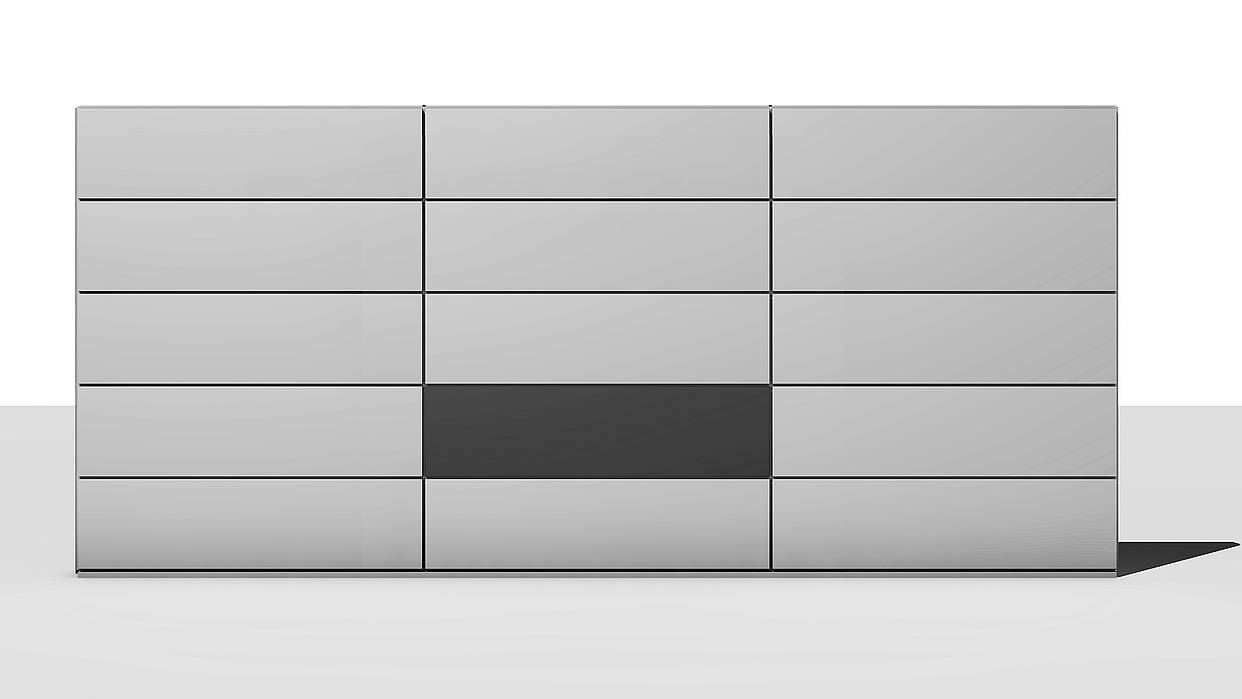

ELEMENT REPLACEMENT

Damage or repair of the Qbiss One wall system, including its range of modular elements, can be performed quickly and efficiently and without any compromise to the façade’s performance. It can also be appropriately repaired using different approaches depending on the nature of the damage.

Option 1

A damaged element can be replaced by a new one, simply by tilting upper and lower neighbouring elements outwards, then removing the damaged element to be replaced with a new one.

Option 2

A damaged element can be replaced by a new one, simply by removing all the elements placed above the damaged one, then replacing the damaged element with a new one and the rest of elements placed back.

Option 3

Element can be refurbished by painting.

* All applications must be consulted and approved by Trimo’s technical support team. Replacement method statements and further instructions are available upon request.